Palmaria palmata Progress Update

Since 2021 we have invested in dedicated research to speed up the development of Palmaria palmata towards cultivation. We now hold 30 strains from five different origins. In 2024, we conducted successful cultivation trials, built on our previous experience.

Our strategy comprises of two distinct cultivation methodologies: ocean, and land-based cultivation.

Ocean Cultivation

Our seeded twine successfully grew into large, uniform blades of P. palmata on the test line at The Cornish Seaweed Company in the UK at the beginning of 2024. This promising result led us to scale up our trials later that year at multiple new sites in different countries exploring different methods, substrates, and deployment times.

Our farm trials step by step:

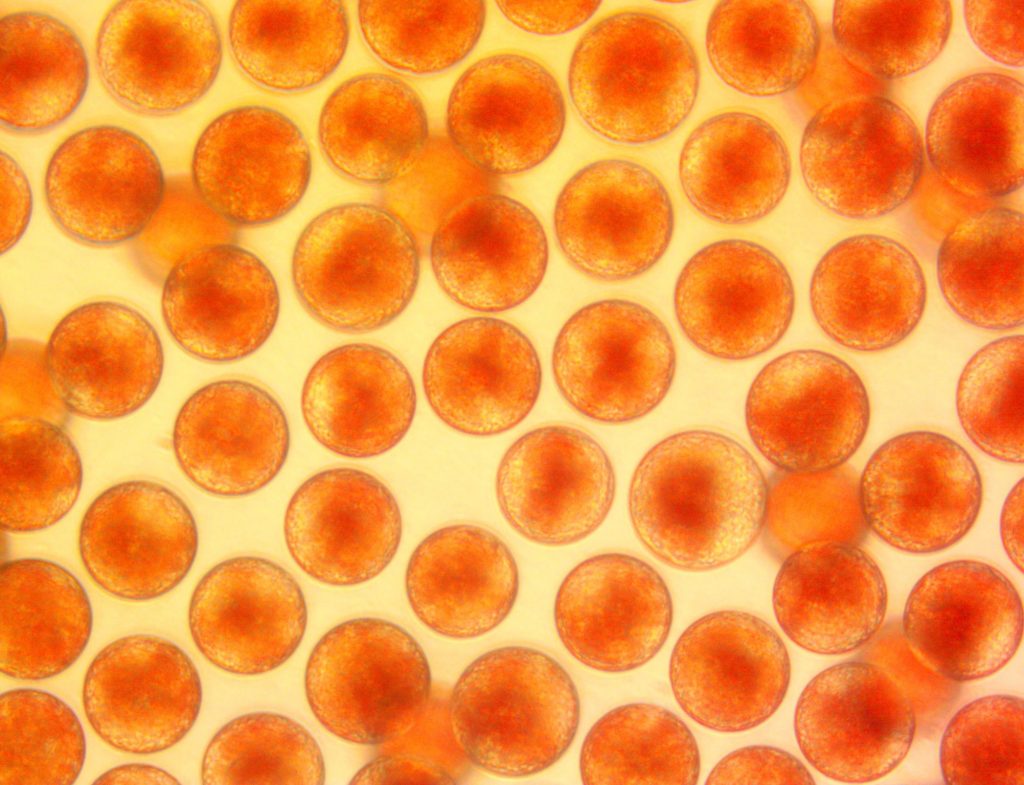

We extracted spores from fertile seedstock, which was collected from the location of the farm. For all new locations, we collect fertile individuals to establish clean cultures for our seed bank. We have developed specific cleaning protocols to eliminate contamination from our spores.

Healthy, clean spores were seeded on specially selected substrates, wrapped around a PVC tube, and then incubated in the ideal environment for the young spores to develop. Here we controlled light, nutrients and water conditions to ensure that optimal clean and healthy development.

After sufficient incubation time in our nursery, the twine with the attached seedlings was wrapped around the cultivation rope for outgrowth in the farm, where they developed for approximately six months.

The lines were eventually assessed, and the data gathered. We added to our understanding of how the environmental conditions affected the grow out and survival of the P. palmata seedstock.

Land-based Cultivation

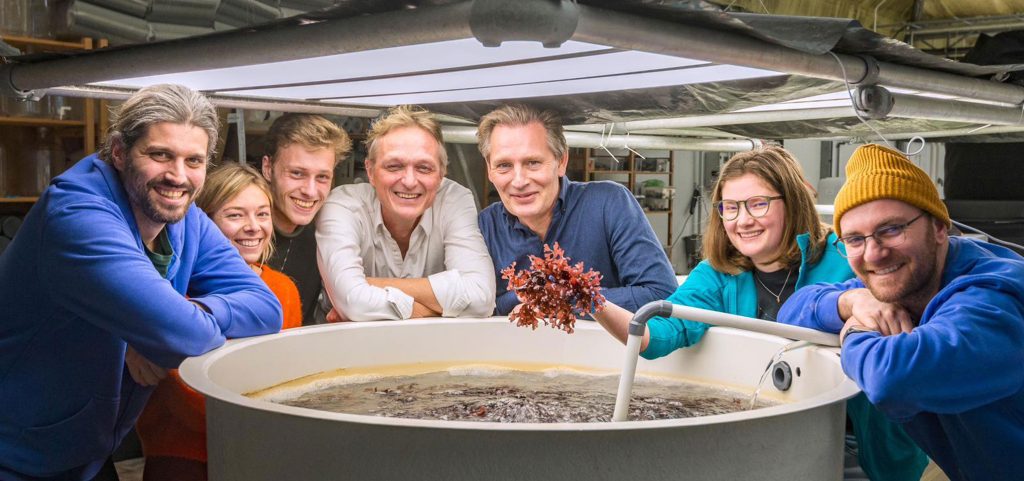

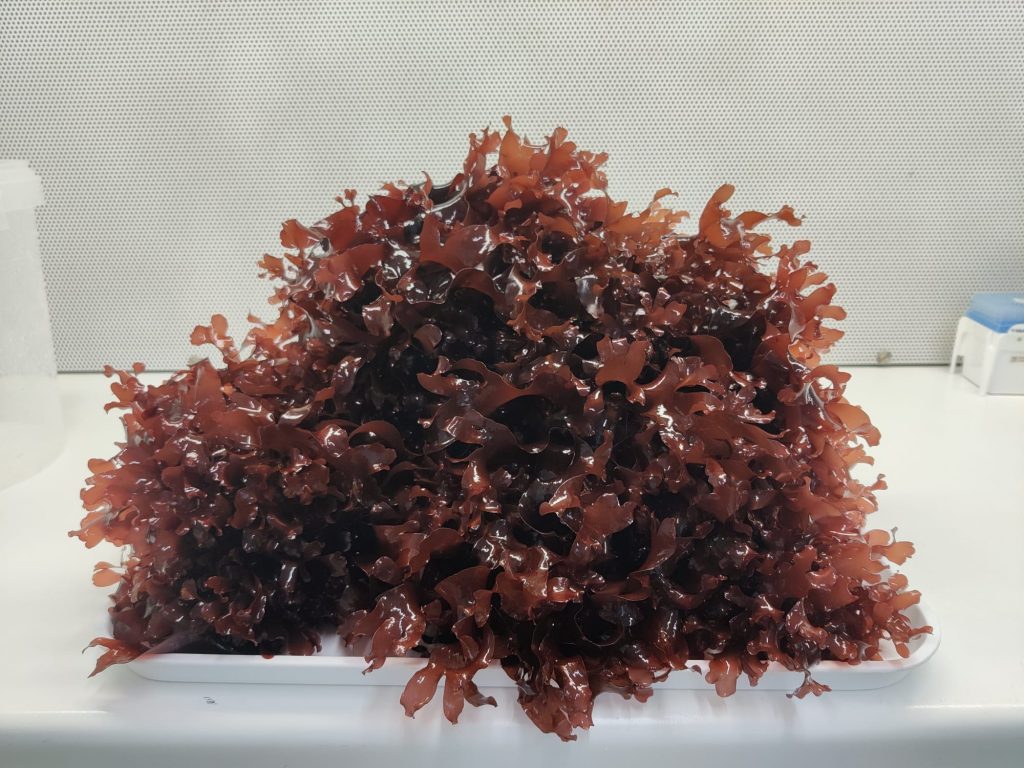

We have developed protocols for year round production of land-based P. palmata, from spore to mature individual. Each seedling can grow to at least 1 kg, and then be fragmented for further growth. Seaweedland was able to obtain a growth rate maximum of 18 % per day using our material in their pilot site at Hortimare.

Our land-based process step by step:

Land-based cultivation limits bio-security risks as the effluent water is cleaned and controlled. This means that P. palmata of various origins may be cultivated at one location. This allows for strain selection aiming at higher growth rate, improved tolerances, or target compound content.

We found that aerated tumbling culture tanks was energy intensive, and limiting in terms of light penetration into the water. Although the material grew out healthy and clean, growth rates were not suitable for production scale. Therefore we decided to explore raceway cultivation to lower the costs and develop protocols allowing for scaled production.

The raceway technology was continuously optimized, and further automated with sensors and environmental controls such as light, pH, temperature, and Salinity. Here we recorded consistent average daily growth rates of 5 % and maximum growth rates of 18 %.

The harvesting process can be partial or complete, by emptying the system for cleaning, and then re-inoculating with fresh seed stock. We found that by replacing the water every 5-6 weeks, our material maintained the highest quality. We are continuing to research how to extend this timeline to reduce operational costs.

Both cultivation methods showed great promise

Land-based cultivation offered a controlled, year-round supply, while ocean-based cultivation remains cost-effective, energy-efficient, and provides valuable ecosystem services. Our research will continue to advance both methods while establishing the groundwork for breeding with our seed bank and experience.

To learn more about our work with Palmaria palmata, contact our researcher Gianluca Bizzaro under gianluca.bizzaro@hortimare.com .